The significance of lithium battery recycling equipment for electric vehicles lies in: reducing environmental pollution, realizing resource recycling, reducing production costs, promoting the development of related industries, and facilitating technological innovation. These equipments are in line with the concept of sustainable development, have positive contribution to environmental protection and economic benefits, and are of great significance in promoting the healthy development of electric vehicle industry and building a resource-saving society.

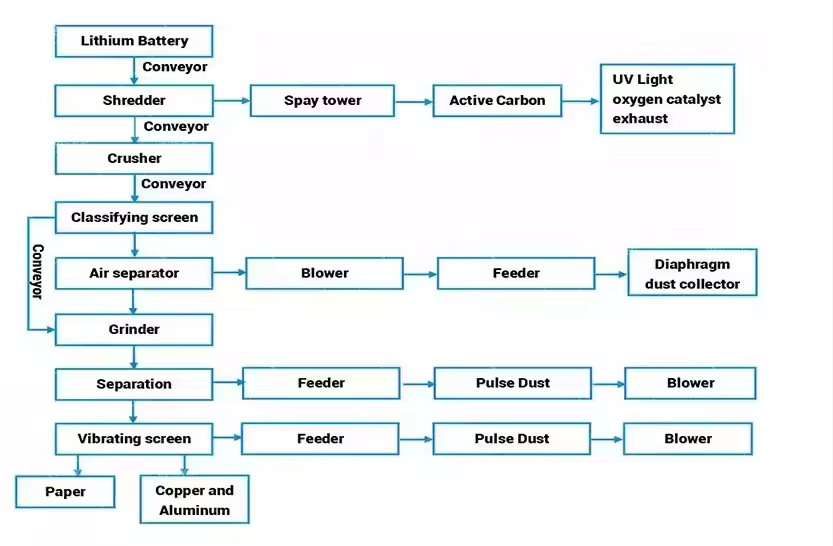

Scrap Lithium battery recycling machine can separate the base metals and graphite powder from the battery by mechanical method.

The whole scrap lithium battery recycling plant process is totally dry and eco-friendly.

Lithium battery recycling

Lithium battery recycling provides essential raw materials for manufacturing new batteries while lessening dependence on finite resources, fostering sustainable development. Lithium batteries contain several valuable materials worth recycling, inculding: Lithium(primary component of lithium batteries), Cobalt, Nickel(provide high energy density), Aluminum (the casing of lithium batteries is typically made of aluminum), Manganese(used to enhance battery performance and stability), Copper(connectors and wires in lithium batteries are often made of copper), Plastics and other components.

1. High-efficiency Separation Technology: Advanced physical and chemical methods are used to quickly and accurately separate

various components in lithium batteries to ensure maximum utilization of resources.

2. Environmental protection and energy-saving design: the equipment is designed with environmental protection in mind,

adopting low energy consumption technology to reduce energy consumption and at the same time reduce pollution to the environment.

3. High degree of automation: the equipment realizes a high degree of automation, reduces manual intervention, and improves

production efficiency and operational safety.

4. Safe and reliable performance: the equipment strictly follows safety standards during the manufacturing process, ensuring

the safety of the operator and the equipment itself.

5. Wide applicability: The equipment is suitable for lithium battery recycling of various types and specifications to meet the

needs of different users.

6. High recovery rate: The equipment can effectively extract the valuable components in lithium batteries, with a high

recovery rate, creating greater value for customers.

7. Easy to operate: the equipment operating interface is friendly and easy to operate, reducing the user’s learning cost.

8. Low maintenance cost: the equipment adopts high-quality materials and design to ensure long-term stable operation, while reducing maintenance costs.

| Model | Capacity |

| XL-500 | 500 KG/H |

| XL-1000 | 1000 KG/H |

| XL-1500 | 1500 KG/H |

| XL-2000 | 2000 KG/H |

| XL-2500 | 2500 KG/H |

+8618339975329

+8618339975329

+86-15037166879

+86-15037166879