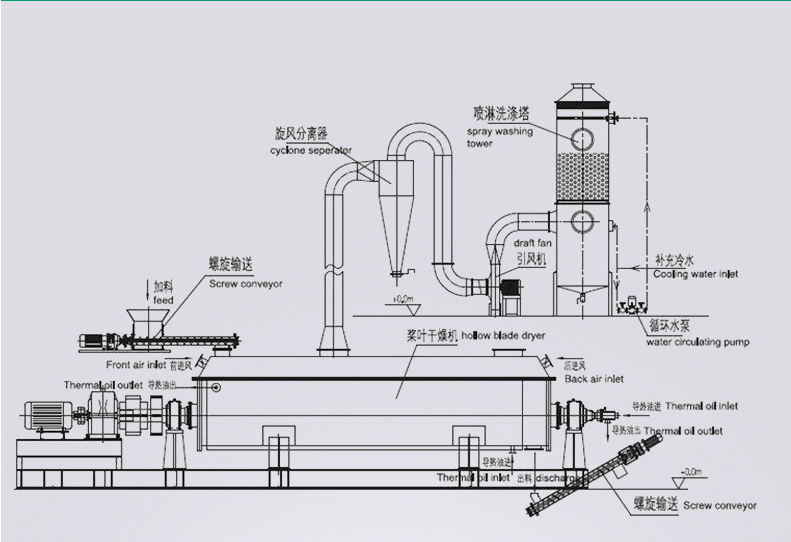

Hollow paddle dryer is a kind of horizontal stirring type dryer which is mainly used for heat conduction. Because the internal hollow stirring blade is similar to the oar, it is called hollow paddle dryer. Paddle dryer has been developed abroad for many years, this model has been developed in foreign countries with two axes and four axes of two structures, a number of specifications of the series of products. As the heat required for drying is indirectly heated by heat conduction, the drying process requires only a small amount of gas to take away the moisture, which greatly reduces the loss of this part of the heat taken away by the gas and improves the utilization rate of heat, and the drying strength of the drying hollow paddle dryer is a kind of energy-saving drying equipment. It is suitable for drying granular and powder materials, and can also dry paste materials smoothly.

Paddle dryer is a kind of horizontal stirring type dryer which is mainly used for conduction. The main structure of the W-type shell with a jacket is equipped with pairs of hollow low-speed rotary hollow shaft, the shaft is welded with a number of stirring blades, jacket and hollow stirring blades, which are passed through the hot carrier, the two heating surfaces at the same time on the heating of the material. Hot carrier is usually fed from the center of the dryer, through the surface of the material layer in a state of agitation, discharged from the other side. The hollow shaft is densely arranged with wedge-shaped hollow paddles, and the hot medium flows through the paddles through the hollow shaft. Unit effective volume within the heat transfer area is very large, the temperature of the heat medium from -40 ~ 320 ° C, can be water vapor, can also be liquid type: such as hot water, heat conduction oil. Indirect conduction heating, no carry air to take away heat, heat are used to heat the material, heat loss is only through the body of the insulation layer to the environment of the heat dissipation. Wedge-shaped paddle heat transfer surface has a self-cleaning function, the relative motion of the material particles and the wedge-shaped surface of the relative movement of the scrubbing effect, able to scrub off the wedge-shaped surface of the adhering materials, so that the movement has been to maintain a clean heat transfer surface.

+8618339975329

+8618339975329

+86-15037166879

+86-15037166879